Top12 Non-woven Fabric Material Suppliers and Manufacturers

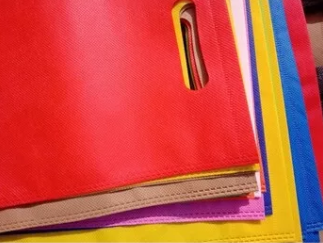

Non-woven fabric is the textile staple fiber or filament orientation or random arrangement, the formation of fiber network structure, and then the use of mechanical, thermal bonding or chemical methods and other reinforcement. Non-woven fabrics are not woven from yarn, but fibers that are bonded together directly by physical means. Non-woven fabrics are soft, thin, wear-resistant, waterproof, moisture-proof, and antibacterial. It is a non-fabric product widely used in daily necessities and medical and health fields. Non-woven fabrics are divided into composite non-woven fabrics and single-layer non-woven fabrics. Different non-woven fabrics have different characteristics, which can be selected according to actual needs.

Non-woven Fabric Features:

-

The quality of light

-

Moderate softness

-

Non-toxic and non-irritating

-

It has the anti-bacterial and anti-corrosion ability

-

Strong degradability

Advantages Of Non-woven Fabrics:

-

Lightweight: Non-woven fabrics are much lighter than traditional fabrics, making them easier to transport and store.

-

Breathable: Non-woven fabrics are highly breathable, making them comfortable to wear.

-

Moisture-resistant: Non-woven fabrics are water-resistant and can protect against moisture damage.

-

Durable: Non-woven fabrics are durable and can withstand repeated use.

-

Cost-effective: Non-woven fabrics are cost-effective and often used in disposable products.

-

Versatile: Non-woven fabrics can be used for a variety of purposes, from cleaning products to medical masks.

Non-woven Fabric Classification:

-

Spunlaced non woven fabric: It is mainly made of spunlaced non-woven fabric by means of machine, acupuncture and spunlaced polymer compounds. Spunlaced non-woven cloth is often made into mask cloth, wet towel cloth, medical non-woven cloth is used in the field of health.

-

Thermobonded non woven fabric: thermobonded non-woven fabric is made by adding sticky compounds on the synthetic fiber network, through the temperature change of synthetic fiber network made of non-woven fabric.

-

Pulp air flow into a network of non woven fabric: by using air flow to blow a single bundle of fibers to the screen, and then reinforce it into a non woven fabric. Pulp air into a net of non-woven paper that is dust-free paper, also known as dry paper nonwovens, often used in health care products, industrial wiping products.

-

Wet non-woven fabric: wet nonwoven fabric is by loosening and mixing different fiber raw materials in water-based media, and then the mixture of fiber suspension slurry is laid into a network in the wet state to form a non-woven fabric.

-

Spunbonded non woven fabric: the fiber, filament spread into the fiber network, through thermal bonding, chemical bonding and other ways of bonding reinforcement.

-

Meltblown non woven fabric: Meltblown nonwoven fabric is formed by extrusion of the polymer to form microfiber, and then the microfiber is stretched and cooled by hot air and blown into the collection network to form a melt blown nonwoven fabric.

-

Needled non woven fabric: needled non woven fabric is reinforced into non woven fabric by needled physical means.

-

Stitched non woven fabric: stitched non woven fabric is woven into non woven fabric by mixing different fiber raw materials through the machine. Needled nonwovens and stitched nonwovens belong to dry nonwovens.

-

Hydrophilic non woven fabric

The Application Field Of Non-woven Fabrics:

-

As a geosynthetic material, it has the functions of reinforcement, isolation, filtration, drainage and seepage prevention in civil construction.

-

Agricultural non-woven fabric, in agriculture, the main use for heat insulation, heat preservation, disease and insect pest control, seedling, etc

-

Non-woven fabrics for medical and health use, including protective clothing, masks, surgical gowns, wipes, etc

-

As nonwoven filter material

-

Used for home decoration, daily necessities, and packaging materials

-

Non-woven fabrics for clothing, such as lining, fusible lining, various synthetic leather substrates, etc

Top12 non-woven fabric supplier in the world

-

Berry Global manufactures a variety of non-woven fabrics, owns the world's leading non-woven fabric manufacturing technology, and is the world's largest non-woven fabric supplier.

-

Polymer Group Inc. is a world-leading manufacturer of nonwovens offering state-of-the-art technology to meet a variety of customer needs. They have a complete nonwovens R&D facility and can produce a variety of materials, including melt-blow printed nonwovens, combustible nonwovens, nonwovens reinforced composites, nonwovens sheathing, electronic nonwovens, and other nonwovens materials.

-

Freudenberg is a manufacturer of high-performance non-woven fabrics used in automotive interiors, clothing, filtration, construction, and healthcare.

-

Kimberly-Clark has a second-to-none production capacity in non-woven fabrics used in filtration, construction, and other applications.

-

Dupont has the absolute right to speak in the manufacturing of industrial non-woven fabrics, and its high-performance fibers are widely used in construction and other industrial fields.

-

Ahlstrom is a supplier of high-performance fiber materials, producing nonwovens for filtration, industrial nonwovens, and other industrial applications.

-

Fitesa is one of the largest manufacturers of non-woven fabrics in the world, with a global reach and mainly used in health, medical and industrial specialties

-

Superchen: Superchen is a leading professional supplier of non-woven fabrics, Our main products are PLA Spunbonded Nonwoven, RPET Spunbonded Nonwoven, PET Spunbonded Nonwoven, SSMMS Spunbonded Nonwoven Fabrics, NYLON Spunbonded Nonwoven Fabrics, MELTBLOWN Nonwoven Fabrics, etc. Superchen factory has a self-built plant of 30000 square meters, up to 12 production lines, and can produce spunlaced nonwoven, spun-bonded nonwoven, melt-blown nonwoven, needled nonwoven, and other non-woven production processes. Our non-woven fabric is made of fiber, polyester or plastic film, and other materials through machinery, melt blown, and other ways of production, has the characteristics of durability, environmental protection, and degradation, deeply trusted by customers all over the world.

-

Fibertex Nonwovens: Fibertex Nonwovens is a manufacturer of nonwovens based in Denmark, focusing on innovation, manufacturing techniques and high quality products. They offer a wide range of nonwovens including combustible, protective, antibacterial, construction, and high performance nonwovens for industrial applications.

-

Glostar: Glostar is a company specializing in the production of specialty nonwovens, offering a variety of materials including polyester, polyester, polyethylene, polyurethane, nylon, and other fabrics. Their products are used in the manufacture of automotive interiors, building and floor coverings, and fabric processing.

-

Fiberweb: Fiberweb is a leading global manufacturer of nonwovens, specializing in a wide range of high-quality nonwovens, including melt-blow printed nonwovens, water-resistant nonwovens, antibacterial nonwovens, magnetic nonwovens, and nonwovens for automotive seat and furniture surface coverings.

-

Freudenberg Performance Materials: Freudenberg Performance Materials is one of the world's leading manufacturers of nonwovens, offering a wide range of materials including fire-resistant, water-resistant, sound-absorbing, protective, and combustible nonwovens. Their products are widely used in the medical, furniture, automotive, construction, and clothing industries.

Asia's largest producer of non-woven fabrics

China. Statistics and analysis of non-woven fabric production in Asia from 2019 to 2021 show that China is the largest non-woven fabric producer in Asia. The main production of non-woven fabric categories is spun bonded non-woven fabric and melt-blown non-woven fabric. At the same time, affected by the normalization of COVID-19, the demand for non-woven products in Asia remains high, and the production of non-woven fabrics in Asia, India, South Korea, and other countries is also rising steadily.

Production of non-woven material

Production of non-woven fabrics used in the fiber mainly: polypropylene (PP), and polyester (PET), in addition to acrylic, acrylic (HDPE), nylon (PA), and chlorine (PVC) fibers can also be used to produce non-woven fabrics. Non-woven materials are made by bonding fibers together in a web or matrix structure without weaving or knitting. The fibers used to make non-woven fabrics can be natural, such as cotton, wool, and silk, or synthetic, such as polyester, polypropylene, nylon, and rayon. The web may be further strengthened by calendering, needle-punching, chemical bonding or thermal bonding. The process of making non-woven fabric is much faster and less expensive than weaving or knitting, making it a popular choice for many applications.