Polyurethane-poly nanofibrous membranes with excellent waterproof

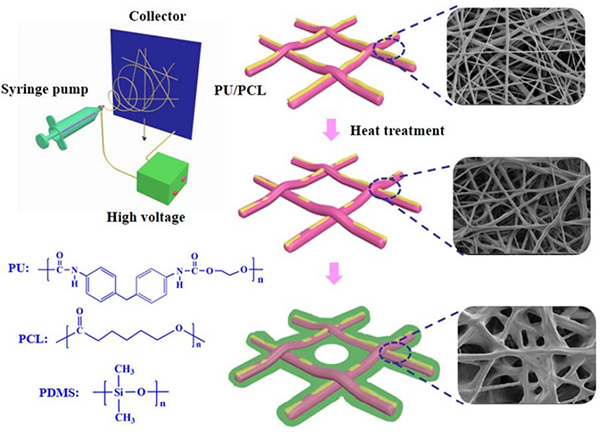

In this study, we prepared polydimethylsiloxane (PDMS)-modified polyurethane-poly(-caprolactone) nanofibrous membranes with excellent waterproof, breathable performances via an electrospinning technique. Field emission scanning electron microscopy, Fourier transform infrared spectroscopy, thermogravimetric analysis, and mechanical testing were used to characterize the morphologies and properties of the composite nanofibers. The fiber diameter and porous structure of the membranes were regulated by the adjustment of the temperatures of thermal treatment and the PDMS concentrations. The fibrous membranes obtained at a typical temperature of 70 degrees C possessed an optimized fibrous structure with a diameter of 514 +/- 2nm, a pore size of 0.55-0.65 mu m, and a porosity of 77.7%. The resulting nanofibrous membranes modified with 5 wt % PDMS were endowed with good waterproof properties (water contact angle=141 +/- 1 degrees, hydrostatic pressure=73.6 kPa) and a high breathability (air permeability rate=6.57L m(-2) s(-1), water vapor transmission rate=9.03kg m(-2) day(-1)). Meanwhile, the membranes exhibited robust mechanical properties with a high strength (breakage stress=11.7 MPa) and excellent thermal stability. This suggests that they would be promising candidates for waterproof, breathable applications. (c) 2018 Wiley Periodicals, Inc. J. Appl. Polym. Sci. 2018, 135, 46360.