China melt blown fabric production experts——Superchen

What is meltblown nonwoven fabric?

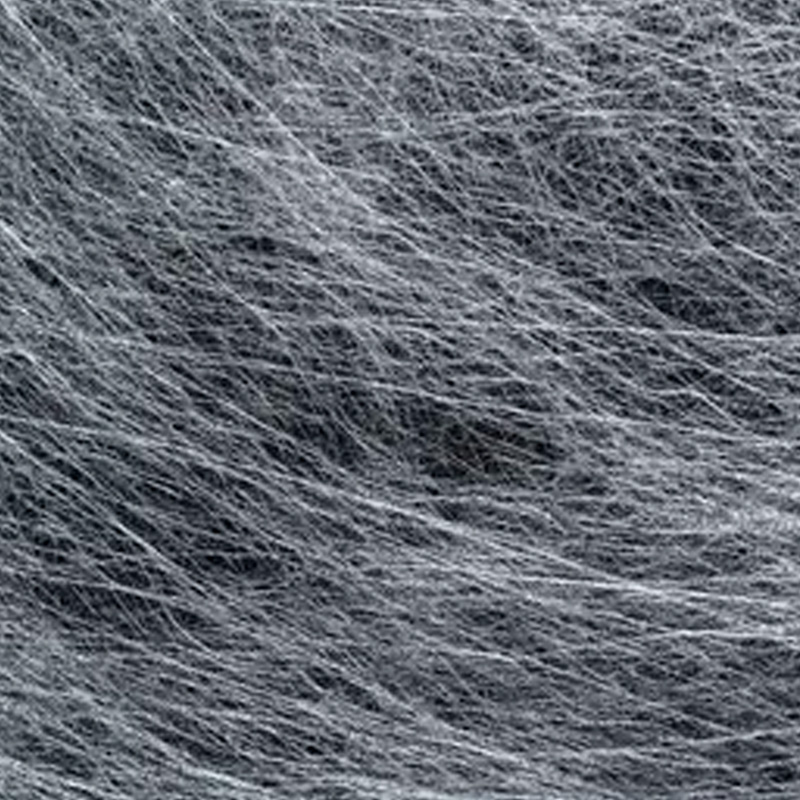

Meltblown nonwoven fabric is made of thermoplastic chemical polymer by melt-blown processing. Its small fiber diameter, good permeability and limit the size of particles that can pass through, so it is often used as a filter material in products such as masks, respirators and microbial filters.

Meltblown technologies

Meltblowing process, also known as meltblowing extrusion, is a single-step manufacturing process in which the melted polymer is extruded from the superfine nozzle of the extruder by high-speed gas flow to form microfiber, which is randomly laid on the conveyor belt or flow collecting network to form melt-blowing nonwoven fabric. It is a traditional manufacturing method of micron and nanofiber. Meltblown technologies makes the production of meltblown fabric has a fluffy network structure, so it has oil absorption, heat insulation, filtration and other characteristics.

The advantages of meltblown fabric

- Filtration: Melt blown fabric through the thermoplastic polymer melt blown into microfiber, microfiber makes it has the ability to adsorb static charge, at the same time melt blown fabric has porosity, improve the filtration ability, play a role in isolation of viruses and bacteria.

- Adsorption: The microfiber makes the melt blown fabric has the ability to adsorb liquid, so that the melt blown fabric has oil absorption, effectively prevent oil pollution.

- High strength: The strength of nonwoven melt blown fabric is improved after melt-blown process. In the application field to provide stability for non-woven fabrics.

- Thermal insulation: melt blown fabric as a clothing mask can neutralize the temperature and absorb heat to adjust the temperature when the temperature is too high.

In addition, melt blown nonwoven fabric also has buffering, stamp, flame retardant, antibacterial properties.

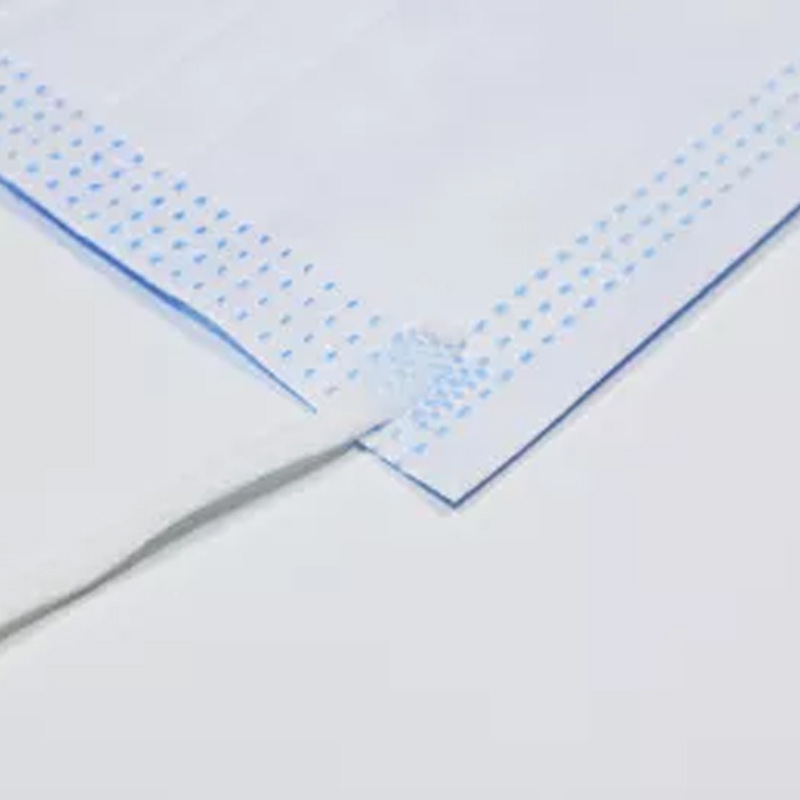

Meltblown nonwoven fabric make masks

Masks are composed of outer, middle and inner layers. The middle layer of medical masks is mainly made of meltblown nonwoven fabric made by meltblown extrusion process. The main polymer used in the melt-blast extrusion process is polypropylene, which is commonly used in the production of surgical or surgical masks and respiratory masks.

Use and application of melt blown fabric

- Medical and health field: It is often used to make masks, disposable surgical gowns, respirators, etc.

- Hygiene products: feminine hygiene products, disposable diapers, etc.

- Filtration field: because of its porosity commonly used to make air filters, liquid filters, etc.

- Home apparel: tablecloth, tablecloth, interlining, clothing, etc.

- Industry and agriculture: geotextile, packing bag, covering cloth, etc.

China melt blown fabric production experts——Superchen

Features Of china meltblown fabric productin line

Melt Blown Non Woven Fabric Factory is equipped with high quality China Meltblown Fabric Productin line that can be mass produced. China Meltblown Fabric Productin Line produces meltblown nonwoven fabrics whose fineness is less than 1.0um. The produced melt-blown non-woven fabric can be used as the core material of surgical mask filtration, which has a good ability to filter bacteria and dust in the air.

China Meltblown Fabric Production Line has the following features

- Production line equipment components of excellent quality, advanced technology

- The production line has a high level of technology and automation

- The equipment structure of the whole production line is reasonable, and the production steps are complete and transparent

We are experts of China Meltblown Fabric. Our Melt Blown Non woven Fabric Factory ranks the top three in China. Our melt blown fabrics are widely sold all over the world and used in various fields.If you have any questions about non woven fabric manufacturer, please contact us.